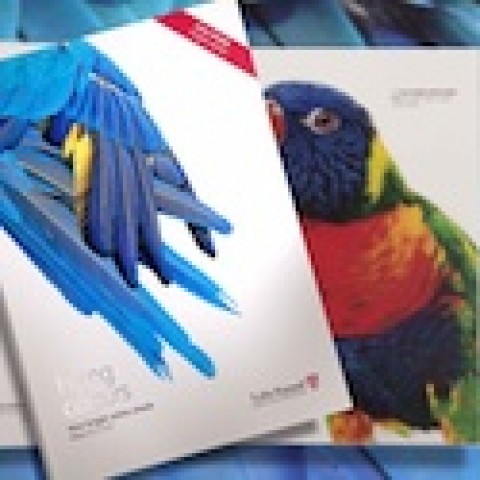

Just before the holidays, I finally received my own copy. I leafed through the book ooohing and aaahing along the way. Who would have thought digital presses could do this?

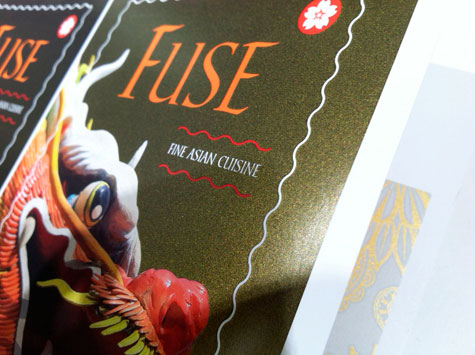

Granted, the “Rebus” book from Margreff is one of a kind. What started out as a promotional piece for DRUPA 2012 soon became a showpiece for great design and superb digital print quality and processes. So this got me to thinking about the astonishing capabilities that digital presses have today, and how quickly it seems to be evolving.

Adding Bells and Whistles

Digital presses are like smartphones. You buy the phone, and it can do the basic calling and texting. To really take it to town, you start adding apps for the things you use or enjoy the most.

As new technologies arise, digital printers can do something similar to their presses – add a function or capability. Which new bells and whistles they choose depends on the market they serve and their clients’ wants and needs.

Here are some of my favorite bells and whistles (as of January 2013 anyway!):

1. PMS Colors

Pantone and press manufacturers have worked together to advance color capabilities – from the number of color choices to the accuracy with which they are rendered. For example, Pantone has certified Kodak’s NexPress, assuring us that it can achieve commercially acceptable color matches for a large number of PMS colors.

HP’s Indigo presses offer various PMS matching options:

- With a fifth color unit on the press, your printer can self-mix or readily order Pantone-licensed spot-color inks.

- Another press configuration can run up to seven colors – cyan, magenta, yellow, black, orange, violet and green – a definite enhancement for the simulation of PMS colors. They claim a 97% match rate.

- HP even offers a Custom Special Inks Service. For years, you’ve been able to take a color sample to your local paint store and ask them to create a matching paint. HP now offers the same for your print project through this service.

2. Print Big

Well, I’m not talking wide format big here (that’s a story for another day), but you can go beyond 8.5″ x 11″ or 11″ x 17″. The average NexPress allows for a 14″ x 20″ sheet size, while newer models go up to 14″ x 36″.

Indigo presses are moving up in size as well. “The new 20″ x 29″ sheetfed press, the Indigo 10000, will begin shipping in March 2013,” explains Vivian Cohen-Leisorek, strategic marketing product manager at HP. “It’s currently being tested in beta sites around the world. The Atlanta HP Graphic Arts Experience Center has had one of these for a few months already.”

3. Print Metallic Inks

To achieve any shiny metallic effect when printing digital, you had to settle for a metallic paper and print CMYK on top. Not for much longer though, my friends. At last year’s DRUPA, NexPress debuted its new Gold and Pearlescent Dry Ink solution.

The beauty of these inks is that you are not limited to just gold … oh no. You can create thousands of different variations of gold-toned tints or different effects by putting combinations of process colors underneath the gold.

These inks are not commercially available in the United States yet, but I will keep you posted. (Between you and me … I know one of the beta testers!)

4. Spot Varnish Effects

Kodak’s ClearCoat has been around for a while. It looks like a satin aqueous coating and can be used as a spot or flood coating.

While not exactly a coating, Xerox for their Color 800/1000 Presses and Indigo presses offers the option of a translucent ink, which features the same visual effects, if not necessarily the same level of image protection.

But wait, there’s more … In the case of the Indigo, this transparent ink can be used to create a raised-ink effect (think thermography).

“Transparent ink and raised printing are mainly the same, but in the case of raised ink, the transparent ink is laid down up to 50 times,” explains Harald Margreff of Margreff Druck und Medien GmbH Germany.

Kodak has its own offering, Dimensional Clear Dry Ink, which enables you to print raised text or textures. The textures especially appeal to our tactile senses. It allows your printed orange to actually feel like the piece of fruit, and your baseball image can have the typical rough leather feel to it.

They’re all simple, affordable ways to add striking creative impact to digitally printed materials.

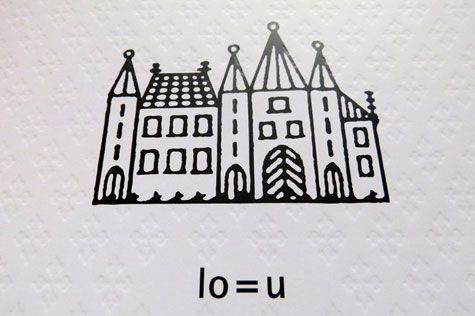

5. Emboss and Deboss

Yes, you heard … well, read right. To be precise, HP uses the expressions “textured effects” and “reversed textured effects.”

“Granted, you cannot compare this effect to classical embossing, but this is not the aim,” elaborates Margreff. “The idea is to give a special effect to a small-run, high-quality print product … and that it does very well.”

The type or patterns to be embossed are impressed into the paper from a mold created on the press using layers and layers of a special ElectroInk. This gives the paper an embossed look that is created without leaving ink behind.

Oh the options … and this is only on the color side of digital printing; wait till we get to the finishing part in a future Paper Tip!

Not every printer will have all these capabilities in-house today, but start the conversation and let them know you’re interested. And wait for the next astonishing options to hit digital presses. As they say: I’m sure there’s an app for that (soon ;-)))!

———-