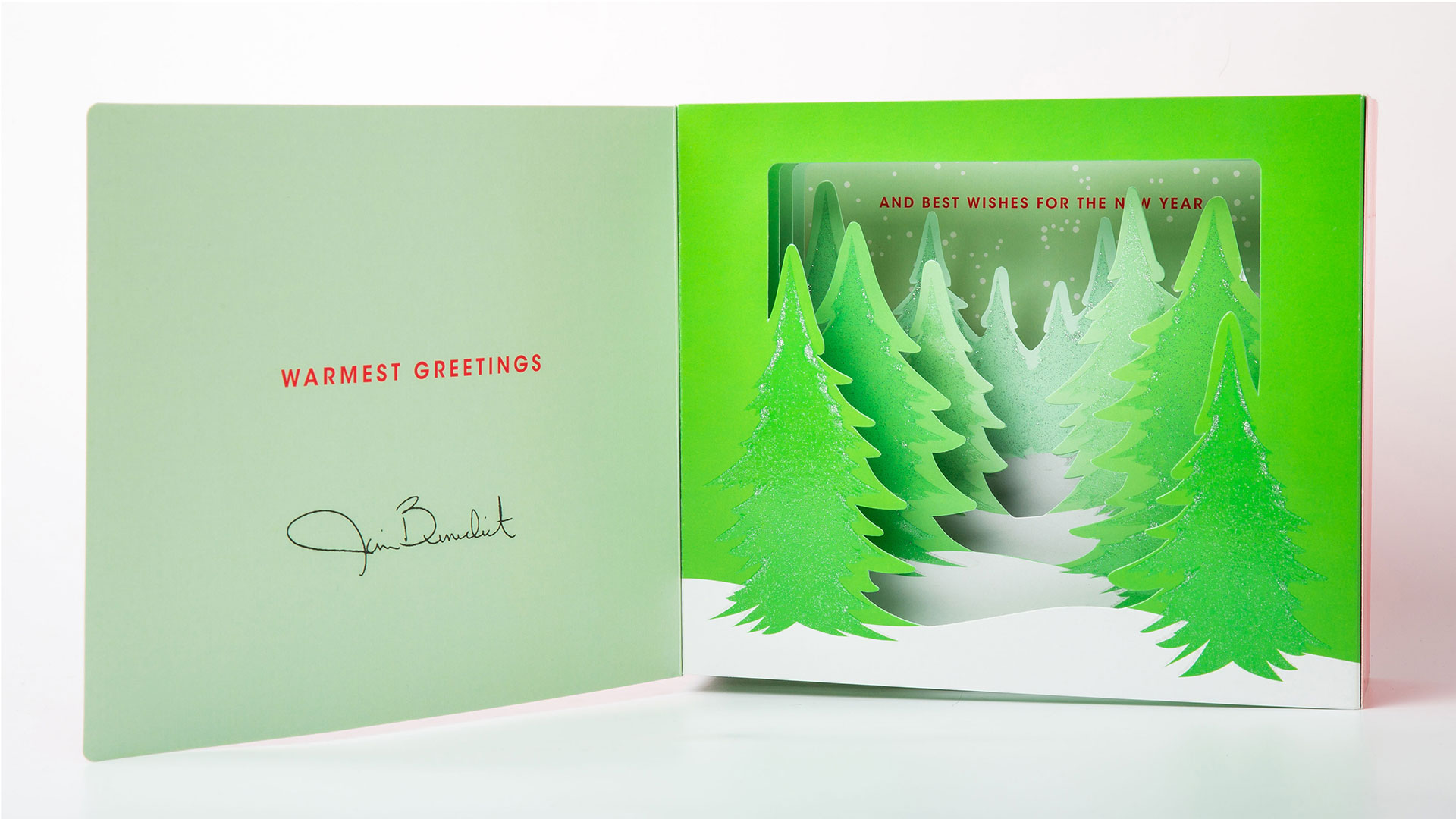

What do you think is waiting for you in your mailbox today? Bills? A few direct mail postcards, perhaps? I’m betting the one thing you’re NOT expecting today, or any other day for that matter, is a surprise. Imagine then how GLS/Next Precision Marketing’s clients and prospects felt when they opened a large envelope over the holidays to find this amazing card inside.

“Happy Holidays” it declares so unassumingly on the front. Yet open it up and it springs from a flat piece into a glorious 3D forest before your very eyes.

This card, designed and printed by GLS / Next, is a marvelous example of how using two already-impressive finishing techniques together can effectively double your impact.

I’m sure one question springs instantly to mind: How did they do that?

- The outside of the card (the cover, sides and back) are all one piece.

- The winter wonderland inside was created as a separate piece.

- The clever die cutting shaped the GPA Ultra Digital Gloss Cover stock into a forest of lush pine trees and rolling snowdrifts. “The tree die cut was 38.5 inches long, which was close to maxing out a 40-inch press sheet,” explains GLS/Next’s Jim Benedict.

- The trees were printed 4-color-process with raised gloss UV silver glitter to complete the whole winter wonderland effect.

Now, to create the 3D illusion of a forest of trees sitting deeper and deeper the moment you open the card, GLS/Next got really clever. The die-cut sheets were accordion folded…with a twist.

- Capacity (like the deep pocket added to presentation folders) with extra room was added at each fold of the sheet and adhered to the card with the help of double-sided tape.

- Each fold is positioned in such a way that, when viewed together, it gives the impression of movement through a thick wood.

- Clever scoring allows this forest to move easily from flat to 3-D.

So attention-grabbing is this one-two punch of die-cutting and folding, you might miss the signature on the inside front flap beneath the words “Warmest greetings.”

It was digitally printed using an HP Indigo 12000. Thanks to that press’ variable-data printing technology, each card bore the signature of that client’s personal account exec – a great way to maintain that oh-so-crucial client-provider relationship.

“Even though it was to be a unique dimensional holiday card, I wanted our customers to also think of how they could utilize the format in their business or use it for a unique product mailing,” Jim points out, and rightly so.

From event invitations to promotions, you can easily see how this format could be adapted to just about any situation where you need to make a dramatic impression. To miss that potential because it is a holiday card would be a case of not seeing the forest for the trees…;-)

PRO members, don’t forget to check out your:

- PRO Tip: Taking Accordion Folds from Humdrum to Extra Fancy

- PRO Tip: The 8 Folds of Highly Effective People

(Not a member? Why not start your PRO membership today?)

Love this piece? Like it, share it and add your comments below.