It seemed like there was a special feeling of triumph and adventure in the air this year. No, it wasn’t on account of the 50th anniversary of the moon landing, impressive though that still remains. Rather it was being able to see – and hold – another example of human determination and ingenuity: the engraving print created by Chicago’s Artistry Engraving & Embossing Co. for Mohawk.

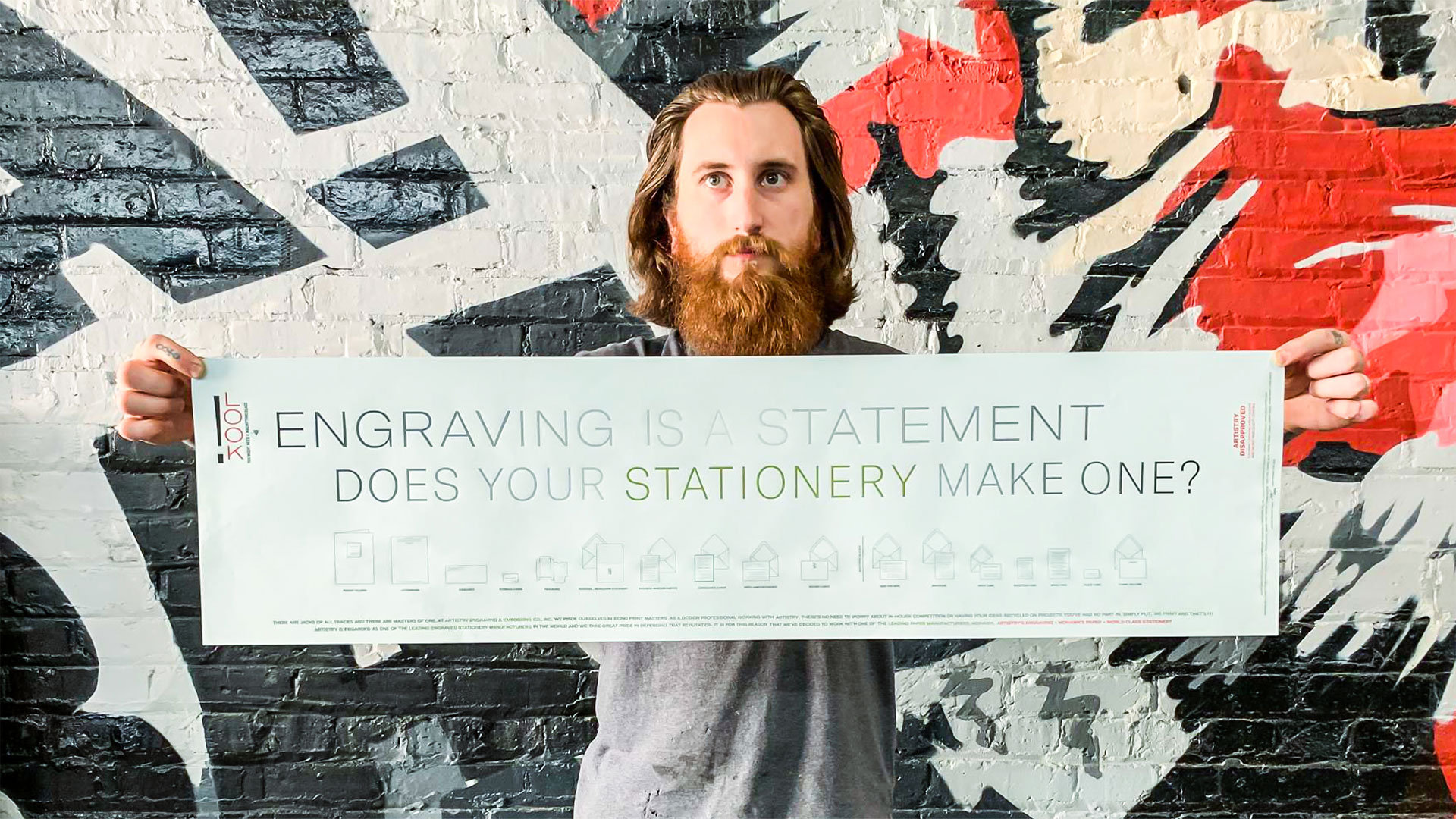

If you caught our recent webinar on engraving [Watch webinar], then you’ve seen pictures of this fascinating “Engraving is a Statement” poster. Still, to truly appreciate it, you have to examine it closely.

That’s really the only way to register the subtle differences in color and the crazy small details engraved in this 10-x-38-inch print produced on Mohawk Keaykolour paper. Artistry Engraving & Embossing’s Philip Gattuso used 16 different colors in all to bring it to life.

Wait – can that be right?

Yes! And to better understand just why that is such an astonishing achievement, let’s review how engraving works in the first place.

What is an Engraving Print?

In the engraving process, your artwork is etched into a copper or zinc printing plate – also called a die. Maximum size for these plates, and thus your engraving artwork, is 4.5 x 9 inches. The finished plate is filled with ink; the plate’s surface is then wiped clean.

Next, slightly moistened paper is pressed against the engraving plate with immense pressure, literally pulling the ink from the plate’s sub-surface and onto the substrate. This causes the engraving ink to sit high on top of your paper.

As you can imagine, this process is extraordinarily tough on the paper used each time you send the same sheet through the press. To achieve all 18 colors, Phil had to hand-feed the sheet through 40 times!

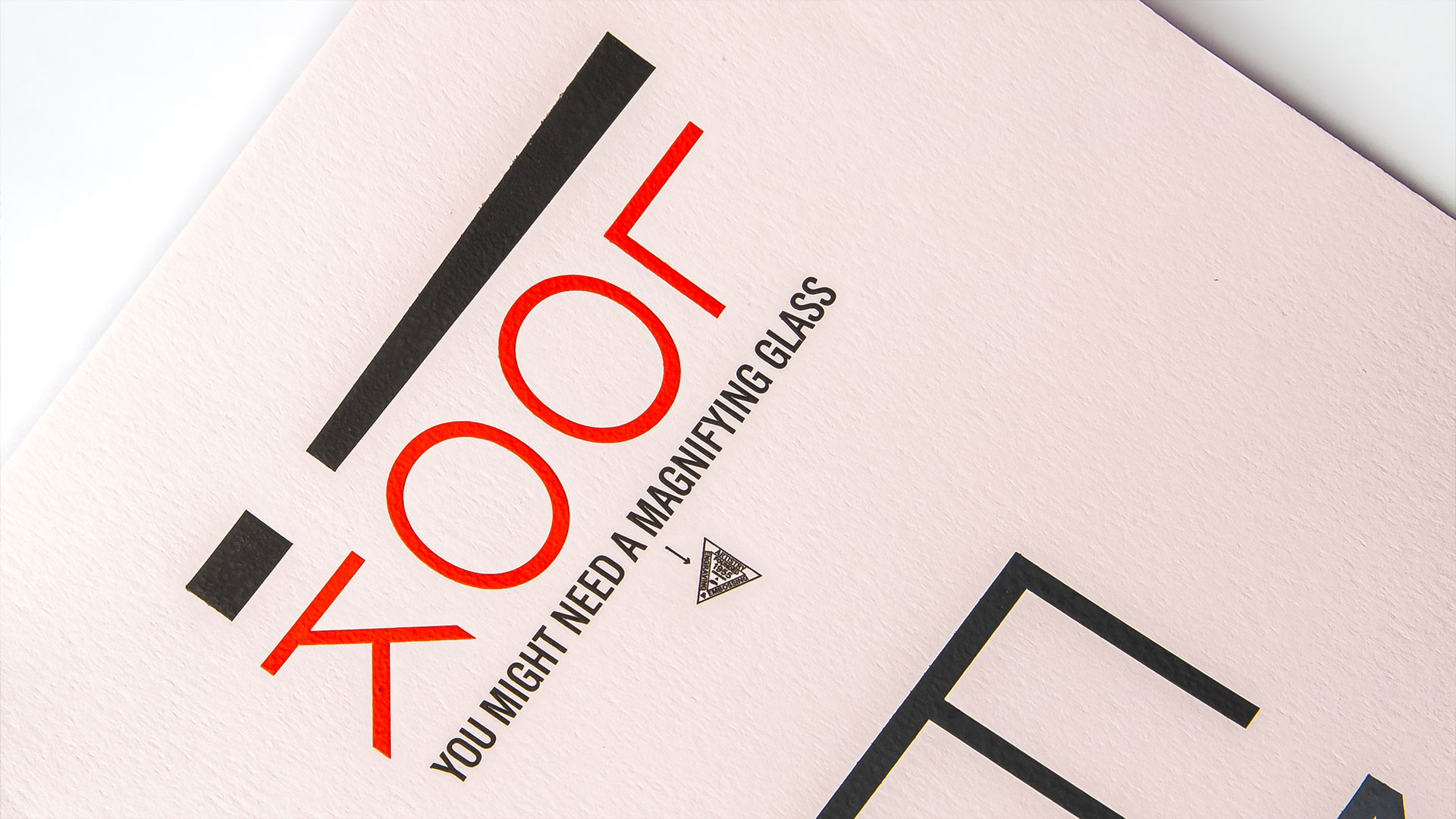

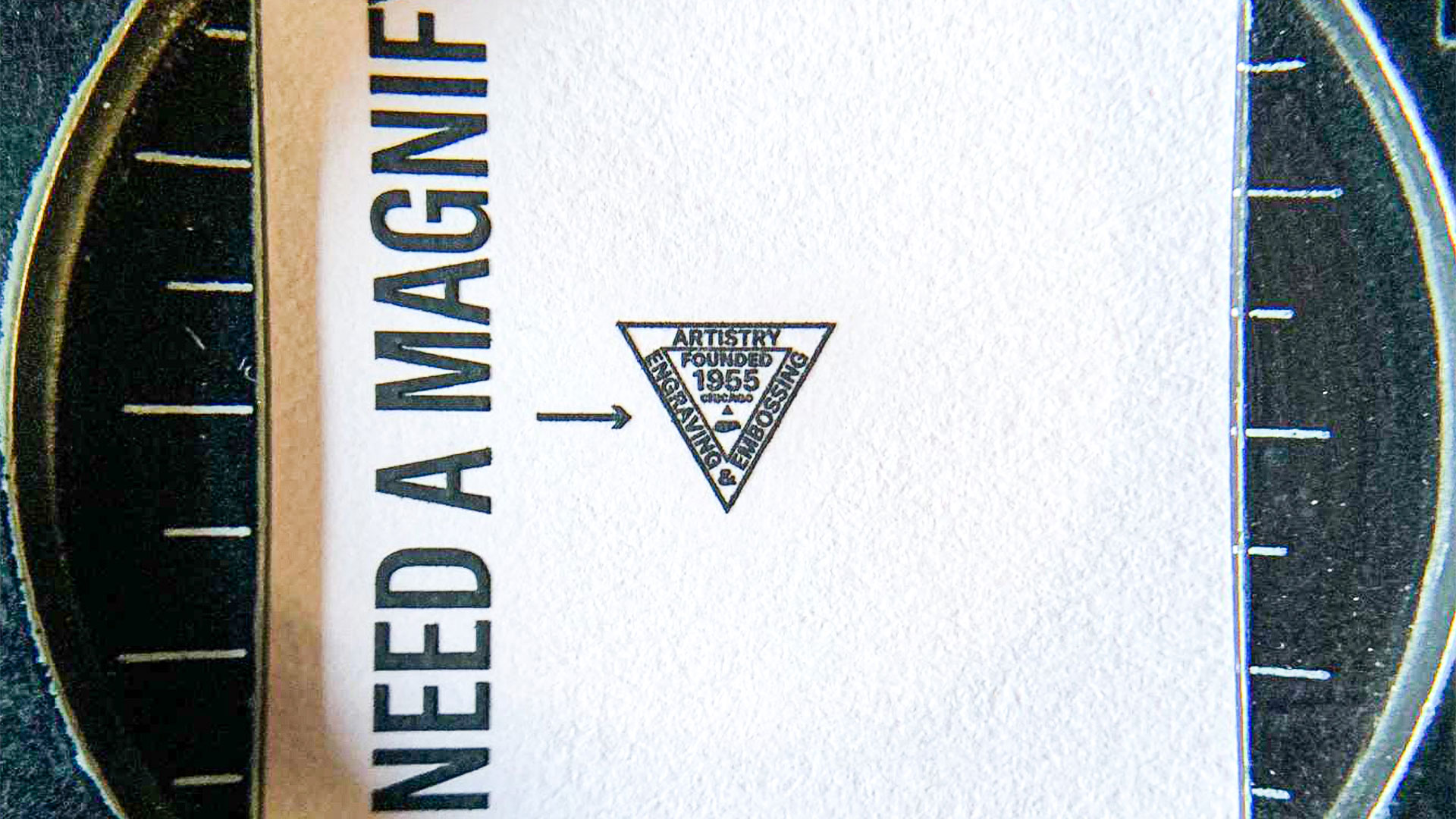

One of the great advantages of engraving is the fineness of detail you can achieve. Take the spot in the corner of the poster that says “Look!” On closer examination you’ll find a “bug” next to it that contains 0.85 pt., 1.45 pt., 1.71 pt., and 2.15 pt. type!

Colored Inks and Papers

Engraving inks are much more opaque than offset ones, which means that you cannot build colors in CMYK as you normally would. On the other hand, they make for great readability, even with little contrast to the paper color.

Due to the opacity of the ink, engraving is a great process for colored stocks, which is where Mohawk’s Keaykolour line comes in – it was the perfect choice for an engraving print. This collection features papers in 43 different colors, so there were plenty of hues from which to choose, and Phil chose several different ones!

Actually, the die size is limited to the size of the die box of the stamping press. There are engraving presses still in production that have a 7″ x 11″ die size capability. Our most frequently used press is a Cronite 5″ x 9″ press which has been “stretched/modified” to 6″ x 9″.

Thank you for that clarification, Ron – that makes total sense. Has anyone ever come across a press with a capacity larger than 7″ x 11″?

From my experience, 8″ x 12″ is the largest die stamping press made for production. This is corroborated in the book “Engraved Stationery Handbook”, authored by Robert Steffens in the chapter regarding press operation. However, there may very well be larger presses that were made.

It is important to understand, that just like steel rule cutting dies… just because the press can hold the die, does not mean it will have enough impression strength/capability to run the die. An experienced engraver can help guide the designer. It may in some cases make more sense to break up the art even if the color is the same and run multiple passes to improve the quality of the print.