Neenah Paper

Neenah Paper and Neenah Packaging are constantly investing in different ways to keep designers and specifiers informed and inspired, whether it’s providing ideas through paper promotions and swatchbooks or being an online resource for information and samples.

Neenah Print Production Manager Carrie Otto has extensive experience in seeing a project begin with design and end with a printed piece, which typically incorporates many different printing techniques and specialty processes. We asked her to share some of her expertise on a few of the special effects she’s worked with.

What is Flocking?

Red flocking begs to be touched, regardless of the message, on this poster from Neenah’s ON promotion.

Flock printing, or flocking, is a process that creates a velvet or suede-like texture by applying short fibers – usually cotton, wool or rayon – with an adhesive. Flocking can be used on almost any surface, from paper and metal to fabrics and glass. The flocked texture, or “pile,” can even be embossed or etched in some instances for extra effect.

How can Flocking be Used?

Flocking can be a great solution for adding a unique look and tactile quality to any project. It’s durable, which makes it perfect for projects with a hands-on appeal such as packaging, posters, greeting cards, book covers…almost anything.

Are there any Special Considerations for Designing for Flocking?

Specifying the area to be flocked would be similar to the way one would design for an area of coating, foil, silk screen, etc. Of course we can never express enough how helpful it is to get your printer involved during the design process.

What is Foil Stamping?

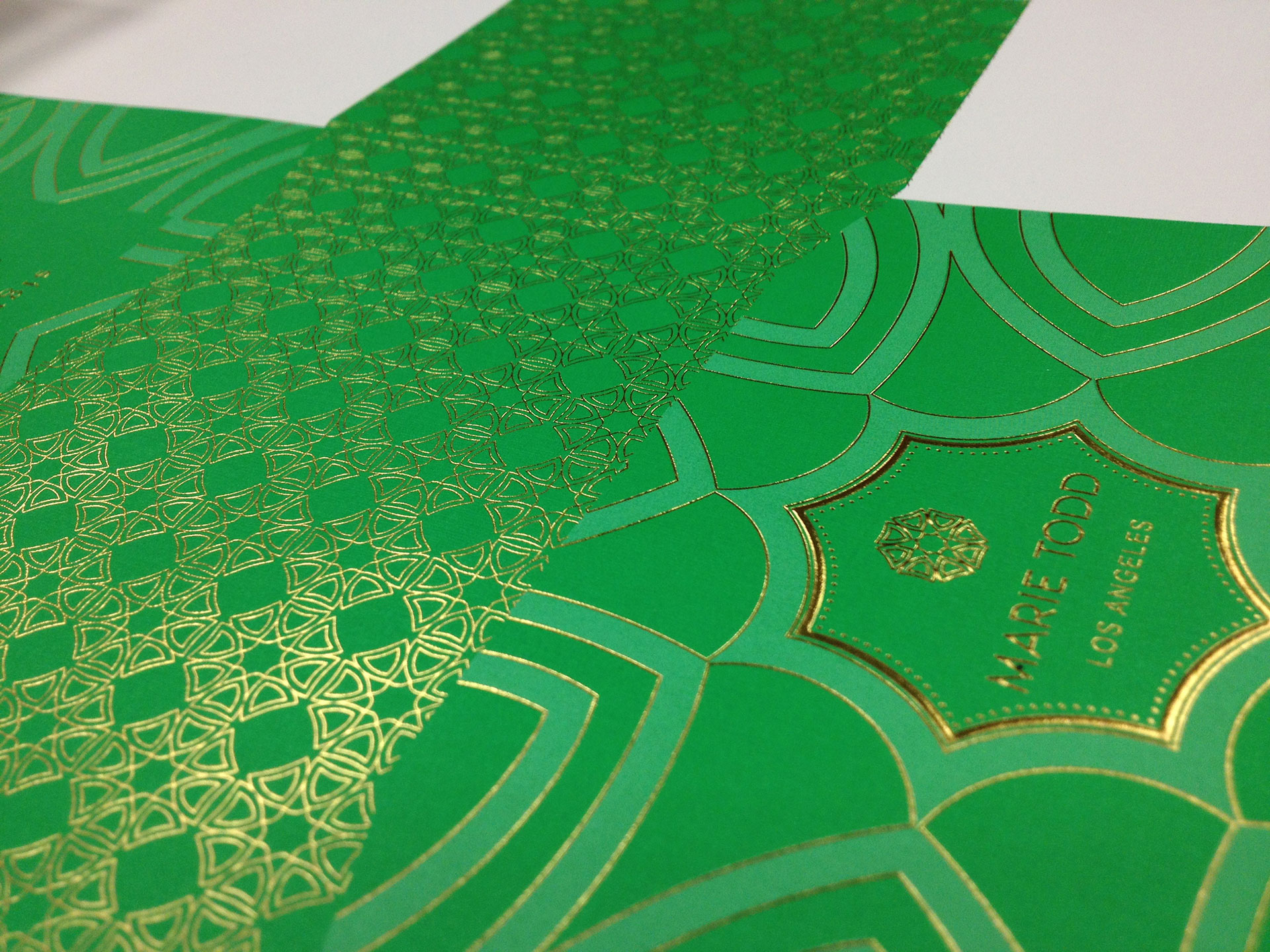

Marie Todd’s line of high-end home fragrances uses gold foil to emphasize this luxury brand.

Foil stamping has been around for a long, long time. It goes back to ancient Egypt, where gold was hammered until it was thin enough to be used as a decorative treatment on armor and the mummy sarcophagus.

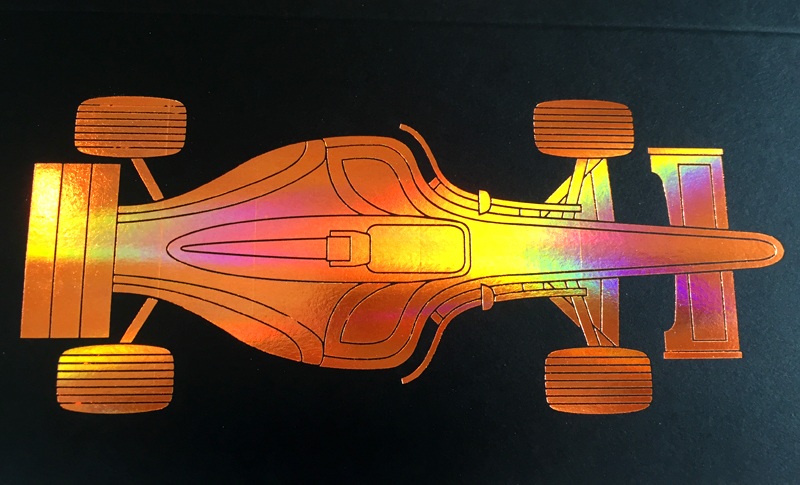

Today there are different types of foil techniques. Hot foil, the most common, is applied using a heat press that activates a thin layer within the foil to adhere to a substrate. Cold foil is generally specified for larger and longer runs because it requires the application of an adhesive layer first, followed by the foil layer.

Scratch-off foil is another way to add a special effect to a project. It’s specified the same way as traditional foil. But some scratch-off foils don’t provide a high level of opacity, which is important to keep in mind when designing the artwork that will be covered by the scratch-off foil. It’s a good idea to make sure your printer understands which areas are to be scratched off.

What are Some Applications for Foil Stamping?

Any project you want to add an eye-catching glimmer to! From packaging, shopping bags and gift cards to folders, book covers, and more.

What is Raised Ink?

Raised digital ink creates a topographical map on this package from Neenah’s Explore promotion.

In recent years we’ve started to see cool new special effects being applied with digital printing. Raised ink is one of those effects. It’s a digital process where ink is applied layer on top of layer to create a raised texture that can emulate embossing or engraving.

What are the Best Applications for Raised Ink?

Raised digital printing tends to work best when applied as fine line work, as in the package shown above. The HP Indigo 7000 recommends a line thickness of less than 1 mm and font size of less than 12 point.

Another advantage of using raised ink as an effect is that, because it’s a digital process, it comes with the advantages of personalization and on-demand printing.

Does Printing with Raised Ink Take Longer to Produce?

Raised digital printing does take a little longer on press because it’s applied one layer at a time. For instance, a project that’s printing 4-color process plus 15 hits of raised ink would travel around the press 19 times before being completed. Your printer can tell you how much time raised ink will add to a production schedule.

To see samples of these and other specialty techniques, contact your local Neenah rep today.

Would a Neenah representative be able to provide a source for Flock Printing? I would love to use the technique but non of my current printers have this ability.

Hi Michael – apologies for the delayed response. Currently there is only one source for flocking left in the U.S.: http://www.greatlakesflocking.com/ . Most printers will outsource their work there. Hope that helps.