Spotlight: The Occasions Group

TOG.ink, the printing service launched last year by The Occasions Group to give you instant nationwide access to a printer with more than 70 years of experience, is now giving you an elegant competitive advantage when it comes to designing invitations: five specialty papers, each with eye-catching borders. Choose from:

- Embossing

- Foil Embossing

- Laser Cutting

- Deckled Edges

- Real Glitter Edges

You can also match these with the best selection of specialty print processes and finishes available from a single printer today. These include:

- Digital printing

- Foil stamping

- Thermography

- Die cutting

- Laser cutting

Simply upload your work to TOG.ink, select the size, paper type, printing/finishing technique and distinctive border, and have your printed pieces shipped right to your door in a matter of days.

5 Ways to Wow

After receiving numerous requests for papers with specialty finishes, The Occasions Group created the Specialty Stocks Collection, featuring the finest of papers embellished with luxurious finishes. This collection provides you with five amazing ways to enhance the power of your next invitations, be they for weddings, product launches, anniversaries, galas, bar/bat mitzvahs, or other momentous events. The collection includes:

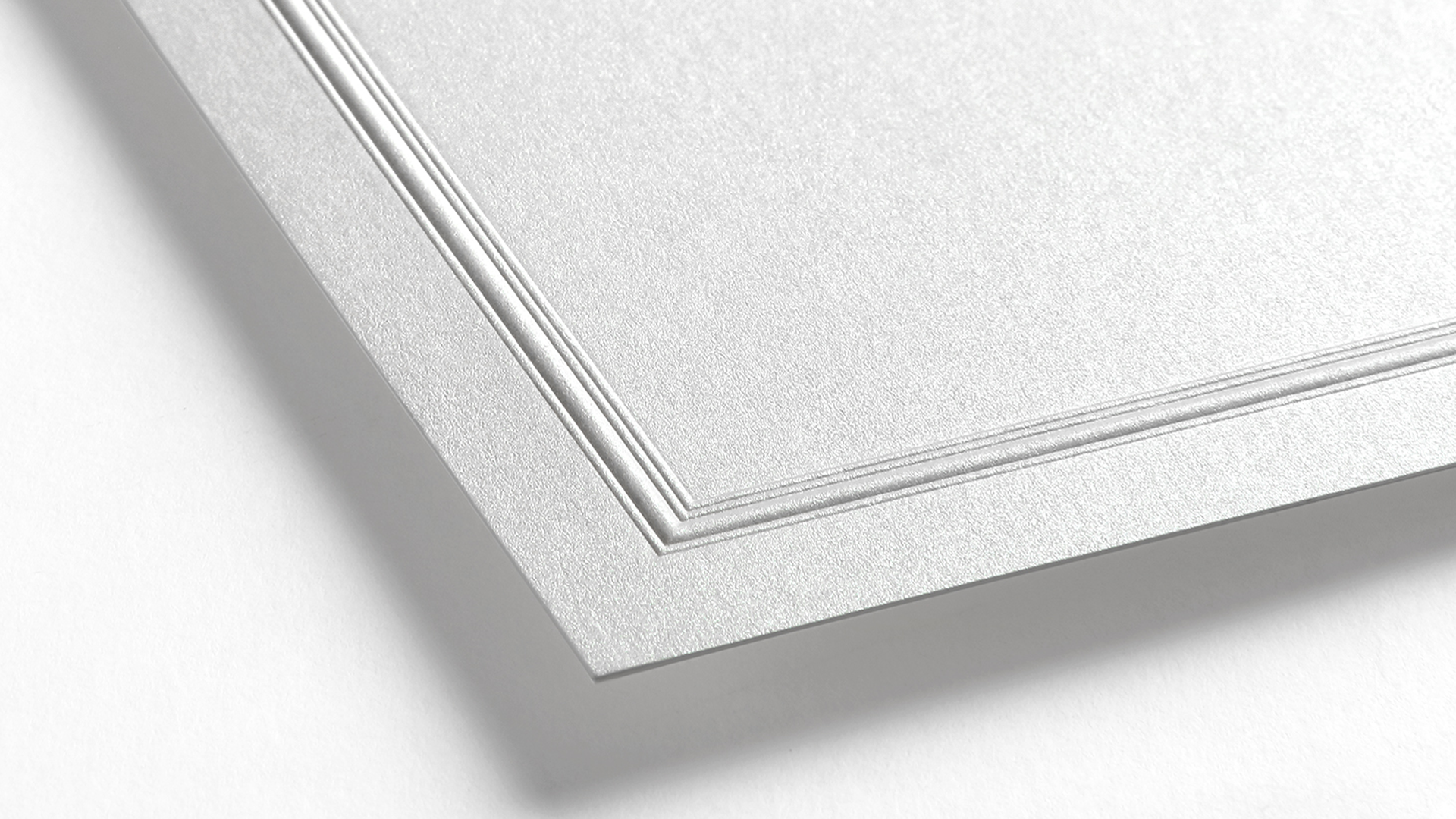

1. Embossing

TOG.ink has added bold embossed frames because they are classic, sophisticated and versatile. Embossing adds dimension to any printed piece, which creates an elegant look that’s hard to surpass.

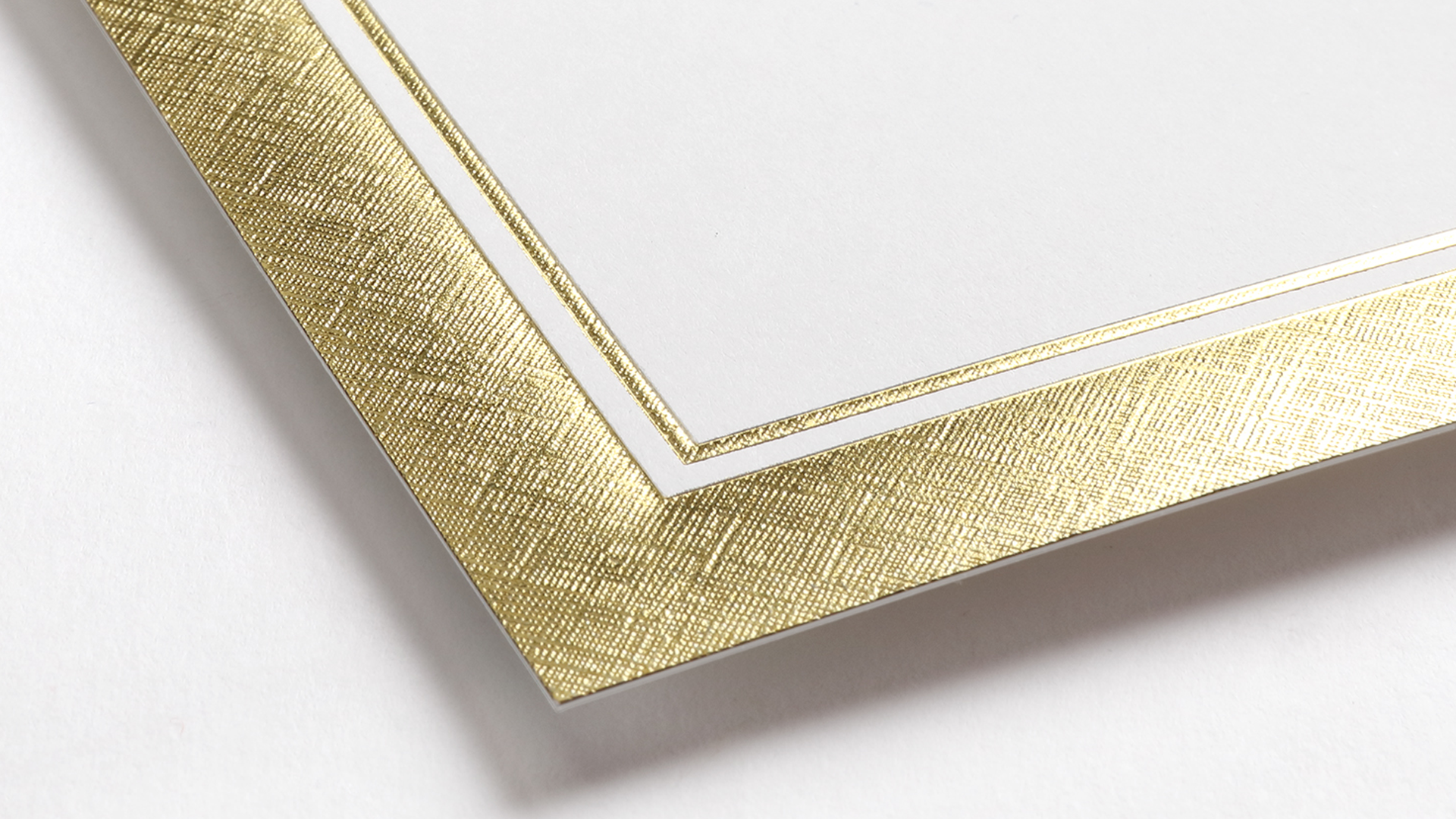

2. Foil Embossing

Foil stamping and embossing are combined to create sparkling frames with depth and dimension. The result is eye-catching and luxurious. TOG.ink offers both pearl foil embossed papers and gold foil embossed papers.

3. Laser Cutting

The precise movements of the computer-guided laser result in stunning and flawless design. The intricate laser-cut border on this paper features filigree and floral corners with touches of embossing to enhance it even more – quite spectacular!

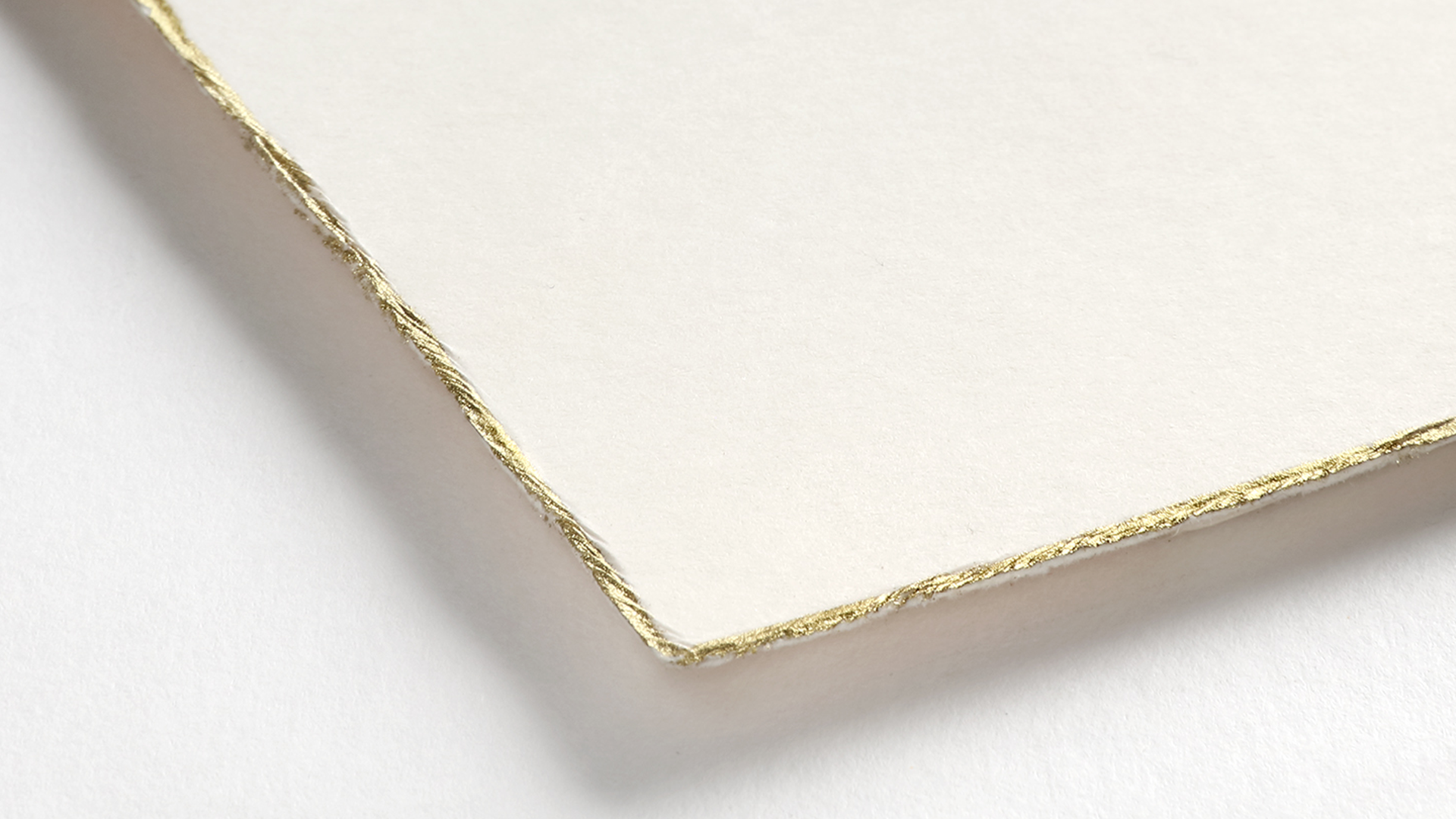

4. Deckled Edges

Historically, deckled edges were a natural occurrence during the papermaking process. Natural fibers were poured to drain and dry on a screen. The deckled edge was actually the feather-like texture left behind along the edges, which was then often removed when the paper was cut to size. Today, a team of skilled paper professionals uses a variety of specially designed tools to grind, carve, cut, scrape and brush by hand the edges of the papers to create this look.

5. Real Glitter Edges

Surface preparation is critical for real glitter application. The surface must be ultra-smooth, clean and dust free. Trained artisans meticulously fan out by hand each sheet or card to the desired width or “border” onto specially designed boards. (It’s imperative that all edges stay straight, clean and evenly spaced.) Each sheet is then carefully glittered, paying very close attention to proper coverage and consistency. The glitter cures on the boards to achieve that sparkling look without the mess of loose glitter.

See Them For Yourself!

Want to see firsthand just how beautiful these papers really are? Enter to win one of 50 Specialty Stocks Sample Packs right now! Hurry – this contest ends April 25th! (North American entries only, please.)

This offer has ended but PRO members can get a copy below.

PROs: Get Your Guaranteed Copy

(Not a member? Why not start your PRO membership today?)